Resonance Enhanced Drilling Technology

What is RED?

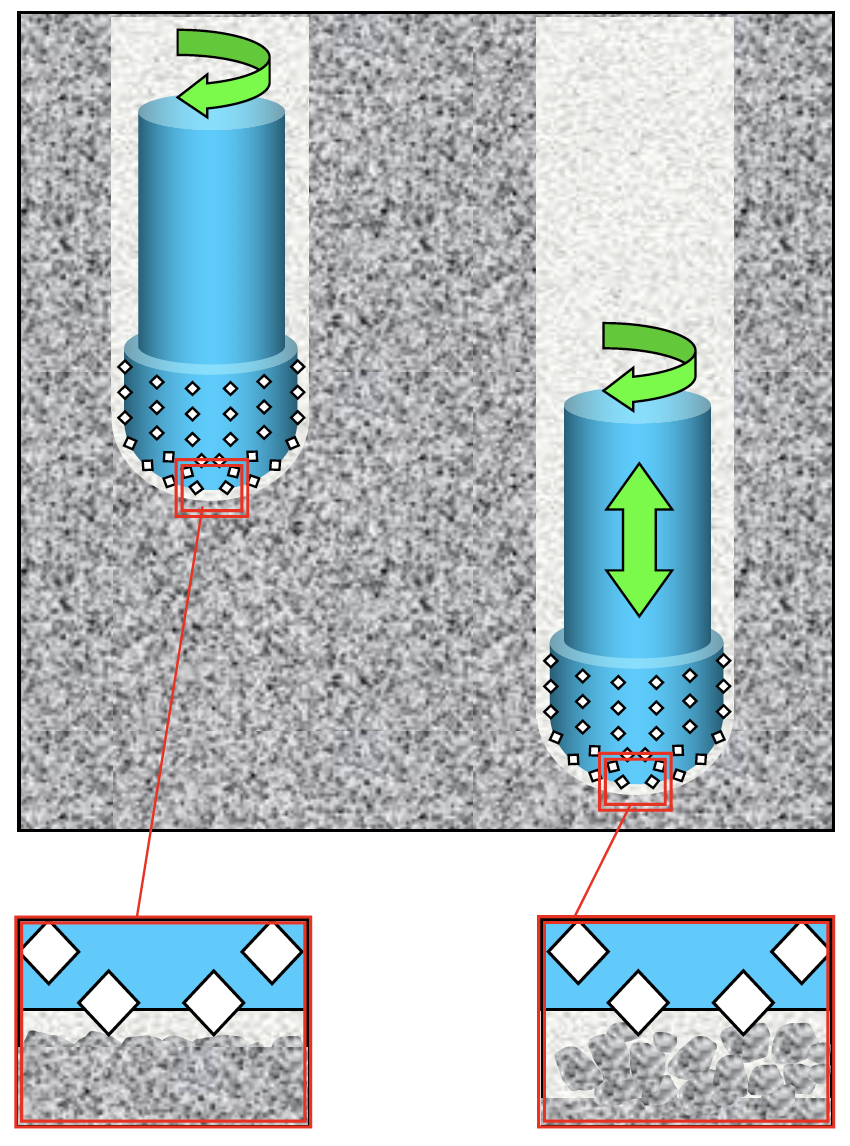

RED is a new borehole creation technology that is versatile, cost effective and has a small environmental footprint. The main idea behind RED is the introduction of axial dynamic stress at resonant conditions in the borehole at the rock-drill-bit interface, which replaces shearing mechanisms with a controllable propagating fracture zone at the rock face as the result of nonlinear resonances. This fracture zone is developed and maintained by the RED actuator and control system positioned behind the drill-bit, which adjusts patterns of dynamic loading in terms of frequency and amplitude according to varying drilling conditions.

The RED technology improves progression rates, reduces tool wear and eliminates undesirable dynamic events. RED is most suited for drilling hard rock formations and is planned for use in borehole creation for the geothermal, rock mining, foundation construction and oil and gas industries. It even has the potential for use in hand-tools and in dentistry.

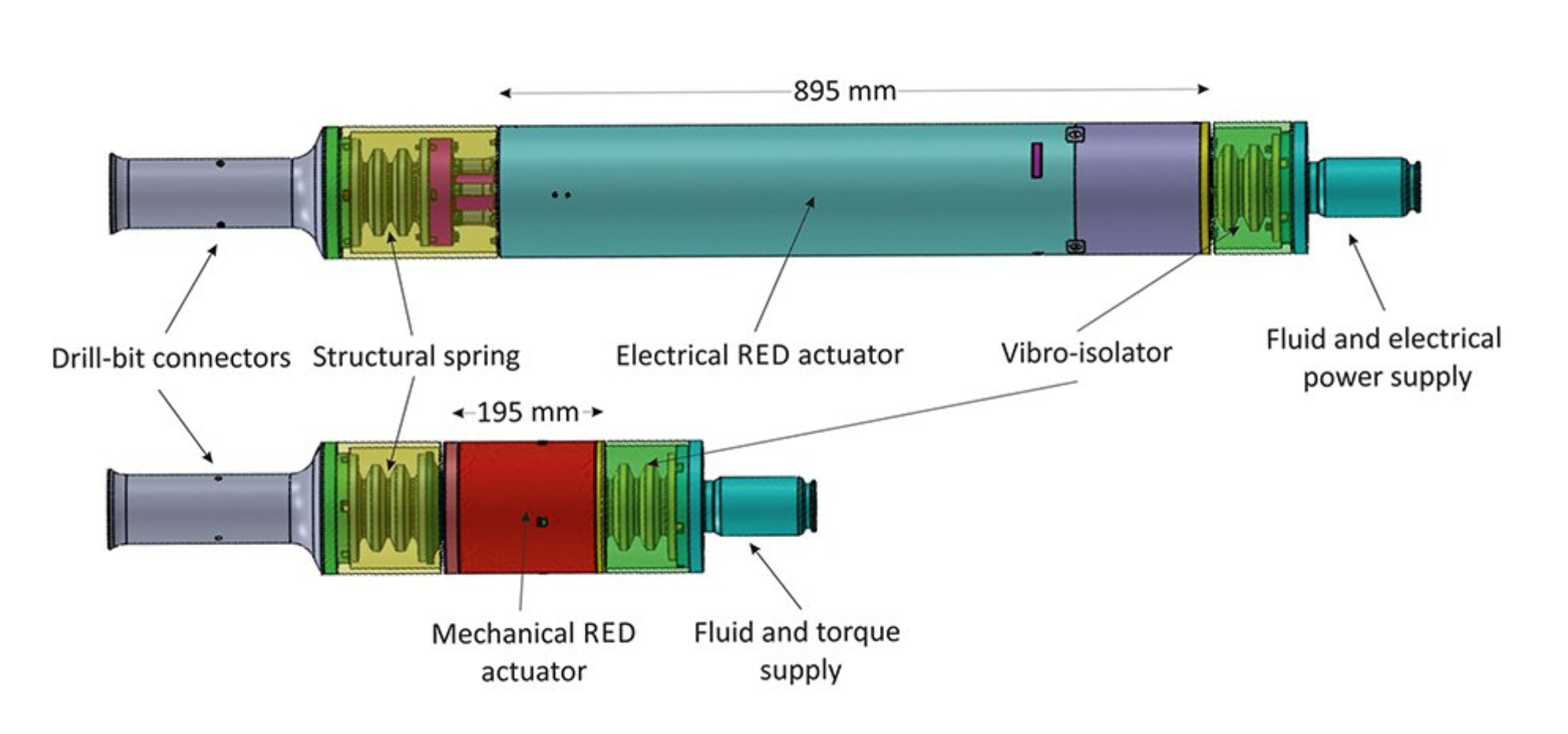

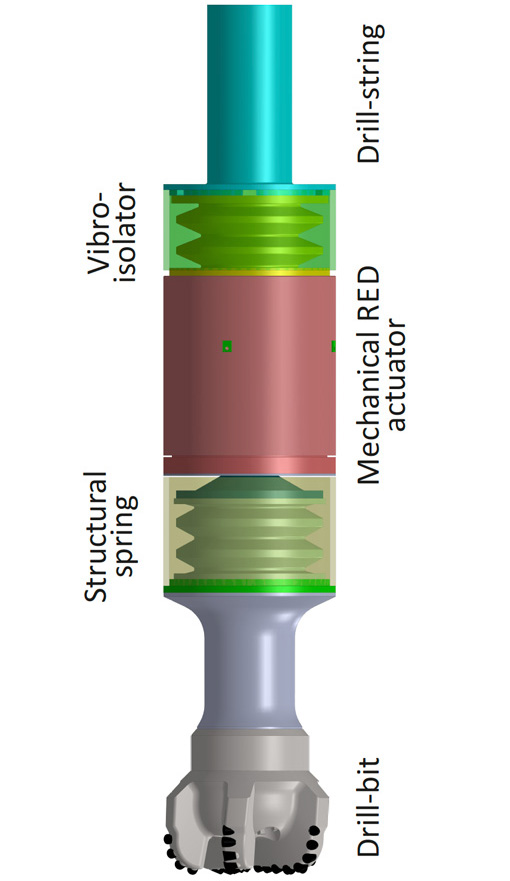

As shown here, the technology comprises a relatively compact RED Module with an integral resonator and high frequency actuator (exciter) that is located in the drill string just above the drill-bit. The actuator, which can be powered by a downhole turbine or an electrical motor, utilises an array of piezo-electric or magneto-restrictive electrically controlled displacement transducers excited at a frequency that develops resonance conditions in the drilling zone. A vibration isolation unit effectively decouples the resonator from the drill string allowing all the drilling energy to be focused at the drill-bit.

This schematic shows the difference in motions at the rock-drill-bit interface between conventional rotary drilling with rock cutting and shearing mechanisms (left) and the RED mechanism (right) applying the high-frequency, low-amplitude axial motions in addition to the rotation of the drill-bit.

The RED technology is compatible with existing downhole drilling and measurement tools and can be run in both “On” or “Off” mode. The On-mode provides the additional controllable enhancement while the Off-mode allows unaffected conventional rotary drilling. When run in the On-mode the weight-on-bit requirements are greatly reduced and this results in significantly lower torque and drill-string vibration. Furthermore, the periodic contact action of the bit results in less friction at the drilling interface. It is in relation to these more benign operating conditions that wider drilling efficiencies are achieved.

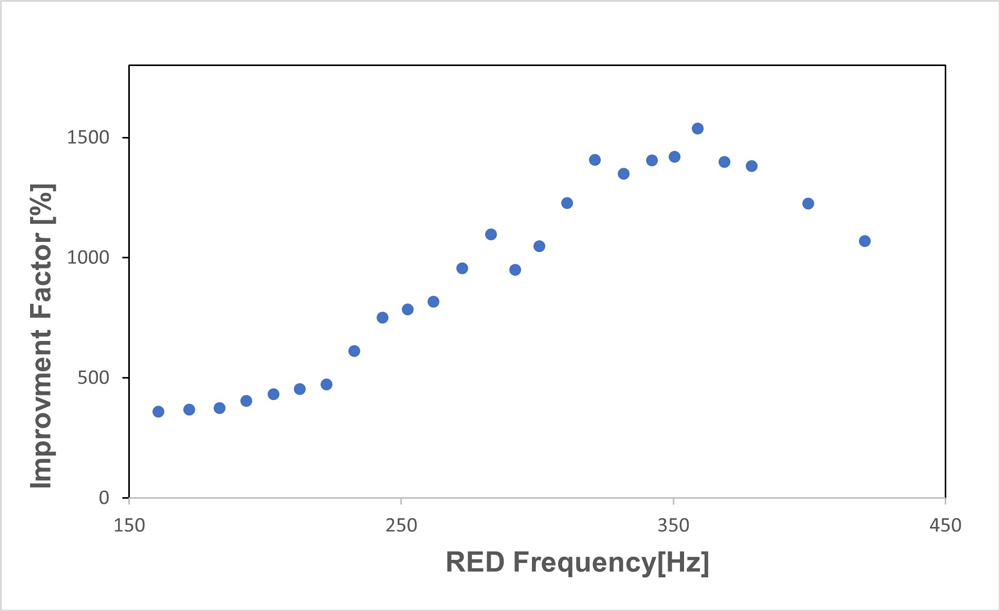

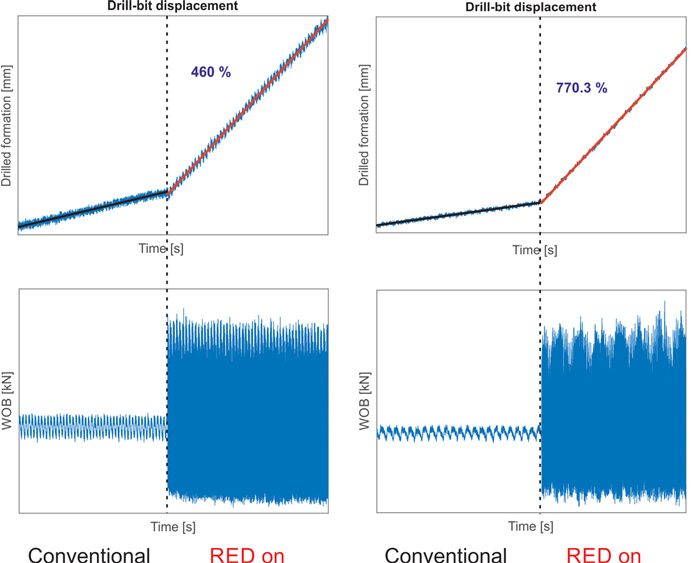

The RED technology has been comprehensively modelled and tested on both small and large scale, custom-built experimental rigs designed initially by the RED research group at the University of Aberdeen and now being developed further by the iVDynamics team. Recent full-scale experiments with industrial partners involved drilling in hard rocks including granite and have shown an unprecedented over five times improvement in drilling progression rates, as shown in the plot below.

A conventional rotary drilling rig can easily be retrofitted with a RED module which is very compact, and currently we have two designs operating with fully automated electrical or mechanical units, as shown in the following schematics:

The Electrical RED Module is actuated using magneto-restrictive principles, while the smaller Mechanical RED Module is actuated by a uniquely designed CAM mechanism that can be driven by a turbine placed behind the RED module.

The transformative advantage that RED has over conventional drilling techniques is its rapid Rate-of-Penetration (ROP) into rock, particularly hard rocks. A typical output from our laboratory experiments is shown in the following plot:

RED induces a dynamic stress field at the rock face

The plots show that for an initial period of drilling, RED is turned off, and so drilling is conventional. As soon as RED is turned on, the Rate-of-Penetration (ROP) increases significantly (red line), with up to nearly 7 times improvement in ROP over conventional drilling, and this result is for granite. The lower Weight-on-Bit (WOB) plots clearly show the highly dynamic nature of the stress field at the rock-bit face interface when RED is turned on.

These results have been determined from our large-scale drilling facilities at the University of Aberdeen, where we have drilled hard rock samples up to six inches in diameter. Our horizontal rig testing facility is shown below:

Horizontal Experimental RED Rig- Large Scale Drilling Capability

iVDynamics greatly acknowledges the joint efforts of the University of Aberdeen and ITI Scotland Ltd. in supporting and executing the considerable research and development activities to-date that has brought RED to its current state of readiness for field trial evaluation and ultimate application to industry.

Benefits

The nonlinear resonances which result in a controllable dynamic stress field and focused impact energy at the bit increases drilling efficiency compared to the predominantly shearing and crushing action of conventional rotary drilling. The key benefits or RED are:

Rapid rates of penetration, up to seven times improvement on conventional drilling, particularly for hard rocks

Reduced rig-time and hence considerable savings on borehole creation

RED’s low weight-on-bit (WOB) requirement results in low down-time and extended bit-life

Low WOB is also beneficial for highly deviated and horizontal wells

RED’s unique mode of operation produces a clean, smooth and stable borehole

A fully automated and steerable RED Module can optimise drilling through rock properties that vary with depth

Potential to access energy resources thought inaccessible up to now; for example, deep, hard-rock geothermal wells

Reach Us

Please send an email to the addresses below or use the form to contact us.

iVDynamics Ltd

Fraser Noble Building, School of Engineering, University of Aberdeen, Kings College Aberdeen AB24 3UE, Scotland, UK

+ 44 (0) 7817145522

Leave A Message

iVDynamics Limited, Registered in Scotland, Company Registration Number: SC594858, Registered Address: 13 Queen’s Road, Aberdeen, United Kingdom, AB15 4YL